After a year with our basic sleeping platforms, two amazing roadtrips, and several long weekend camping trips, it was time to upgrade our Transit Connect’s camper van conversion. We were really starting to picture how we could build a modular sleeping platform with storage for our camping and scuba needs using t-slot aluminum structural framing (also known as 80/20 framing, after the 80/20 company, a leader in this system).

Everything we talked about in our van conversion planning post last year still rings 100% true. We talked about defining your requirements, planning and designing accordingly, and iterating. But as much as you can try plan in advance, you really need to spend time in your van to truly understand how you’ll use it. That’s why we kept it simple at first, and only after a year are we taking the next step (although we did do some minor upgrades along the way).

Contents

Design

Our original construction idea was based on a full wood construction using baltic birch plywood. But things really started coming together when we focused on t-slot aluminum. The material cost would be a bit more, but the construction work would be greatly simplified, and we could make it more modular and upgradable.

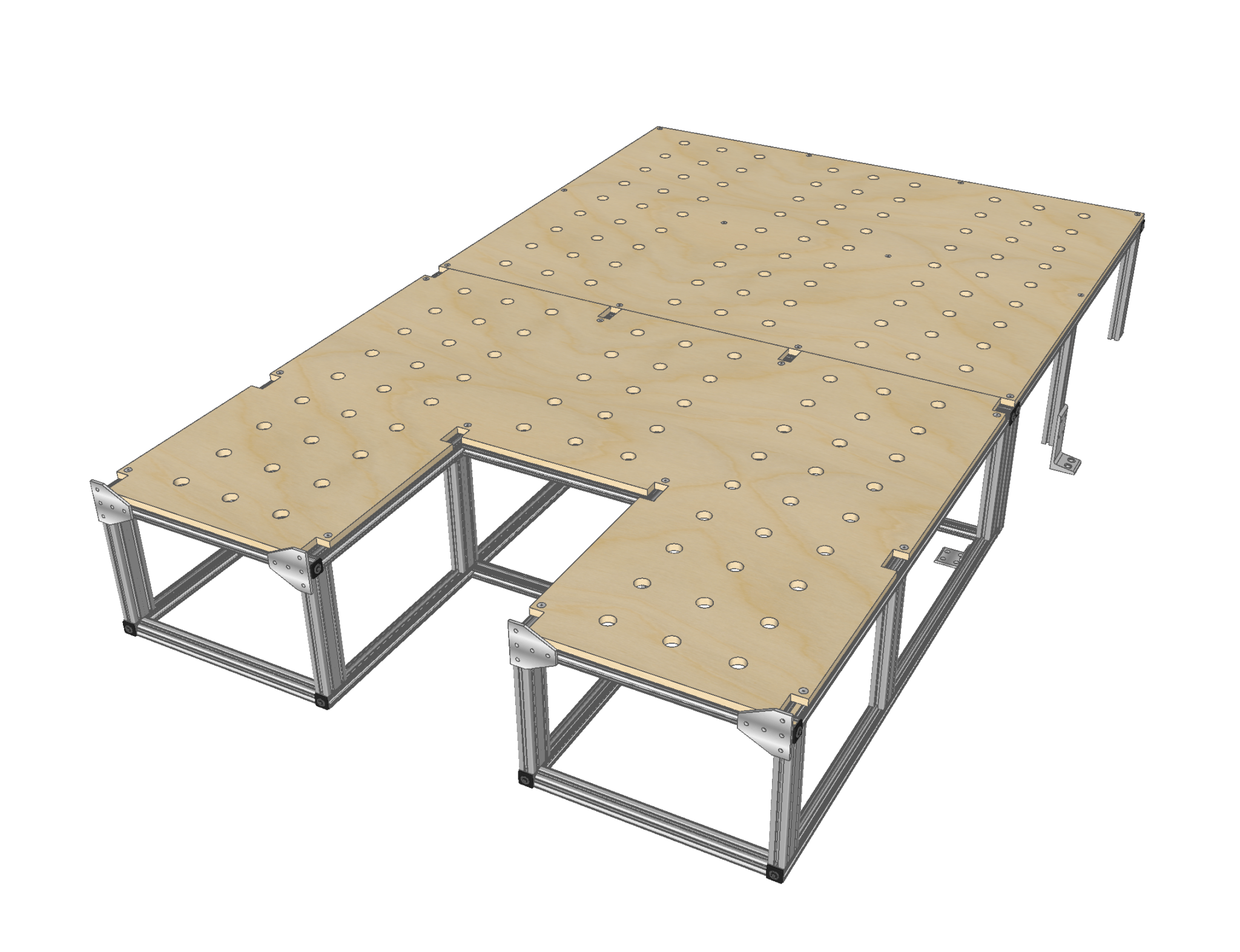

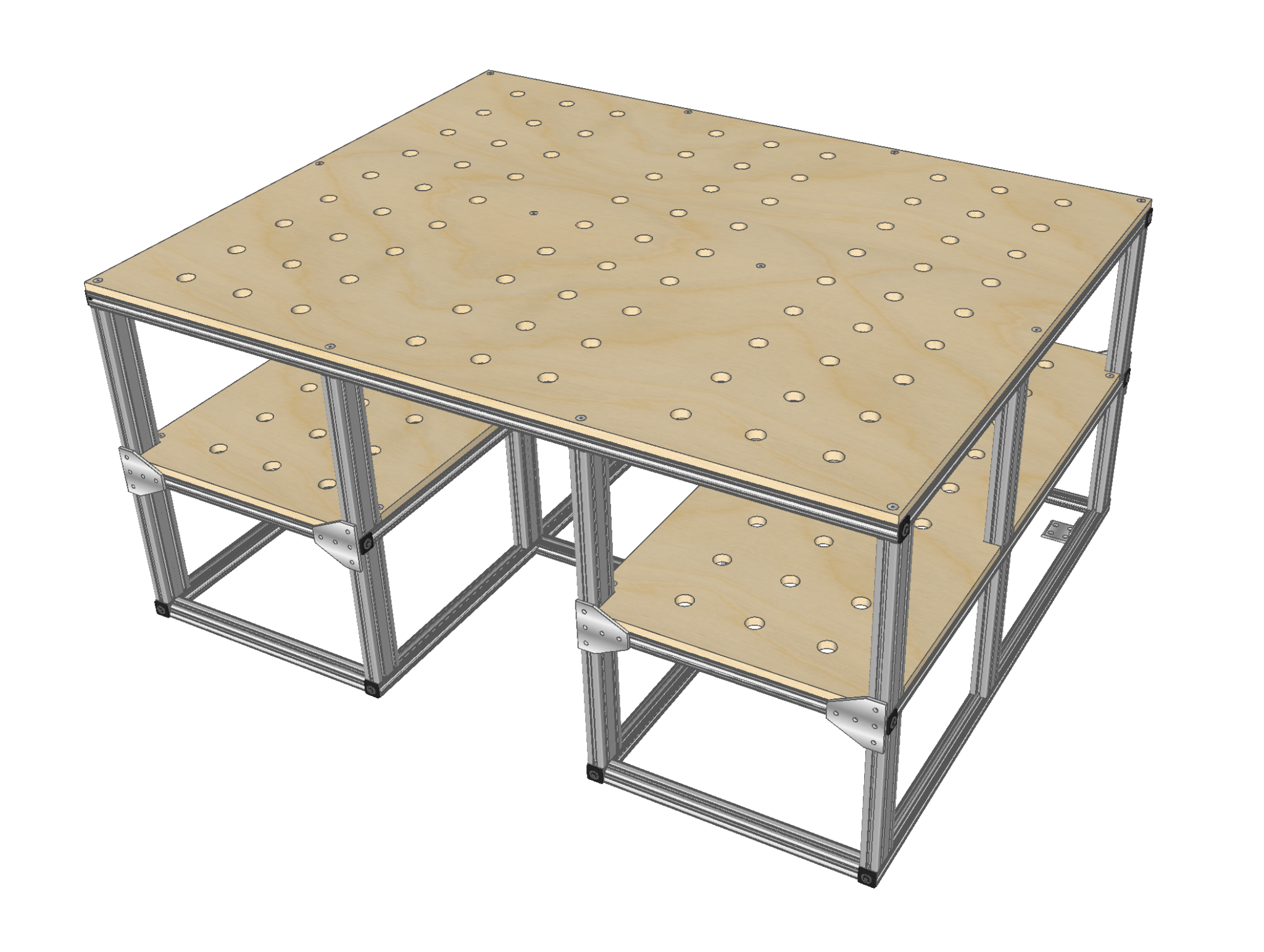

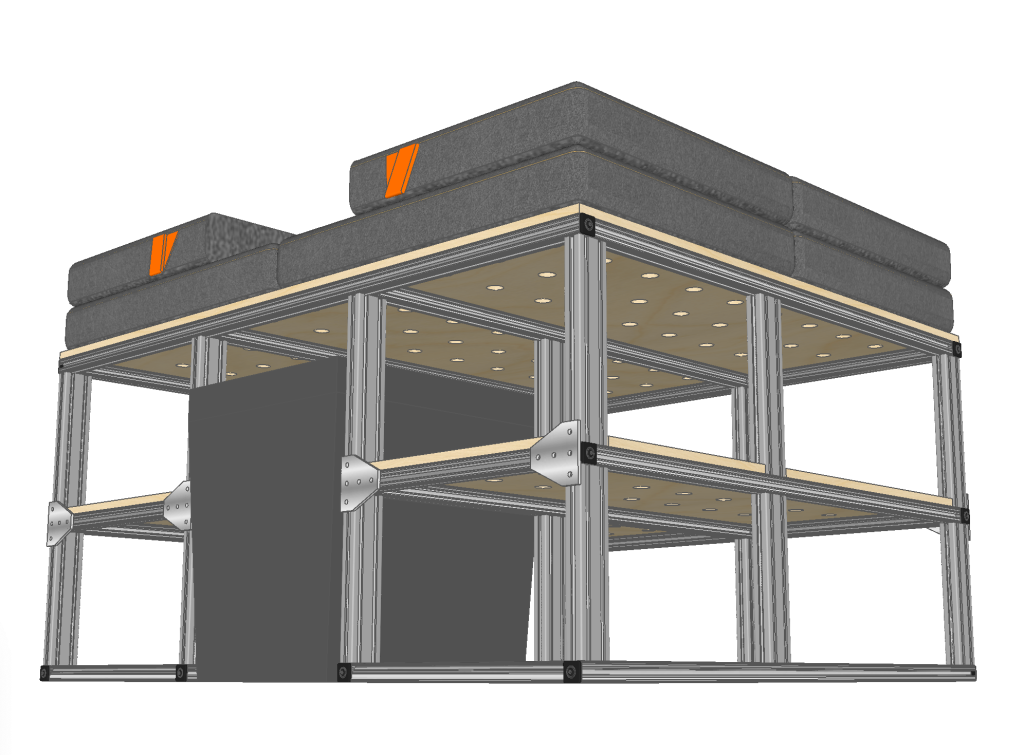

Since any sleeping platform in our small Transit Connect would take up the entire floor space, we wanted a convertible system so we could haul cargo when we weren’t camping. We conceived a design in two pieces that could stack and form shelving. Whether in sleeping or shelf configuration, we’d have lots of storage space.

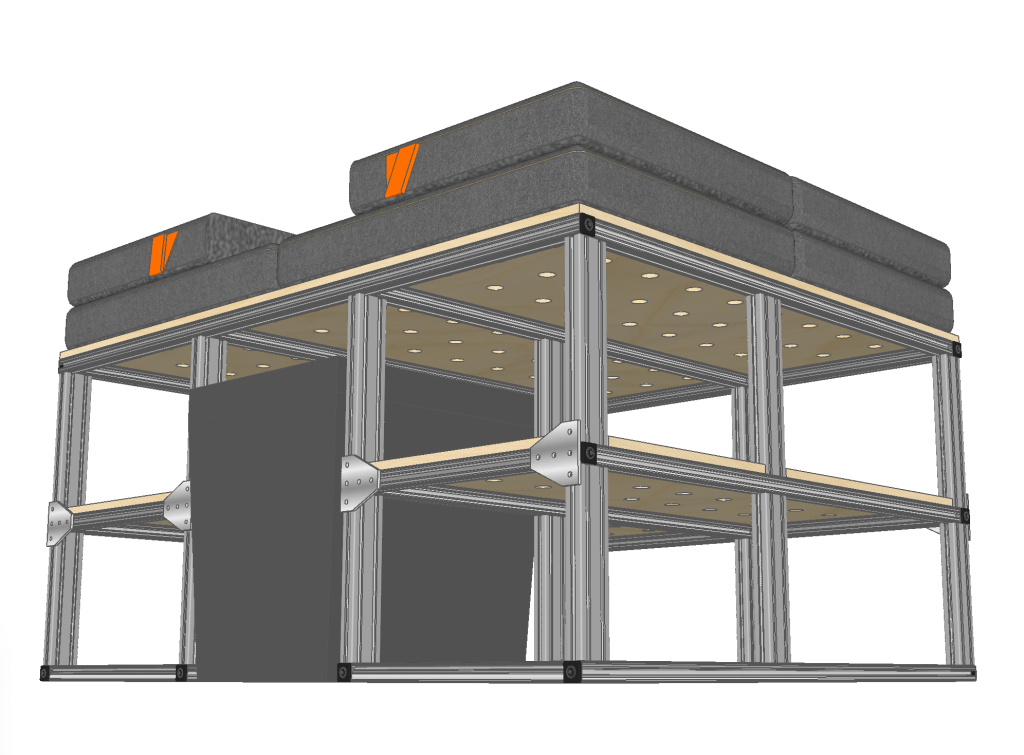

The trick was creating a flat, even sleeping surface that would support two adult bodies when in sleeping mode, while aligning the platform legs to allow the shelf configuration. A clever feature is the small cutouts in the baltic birch platform for the upper shelf legs to lock in when in the shelf configuration.

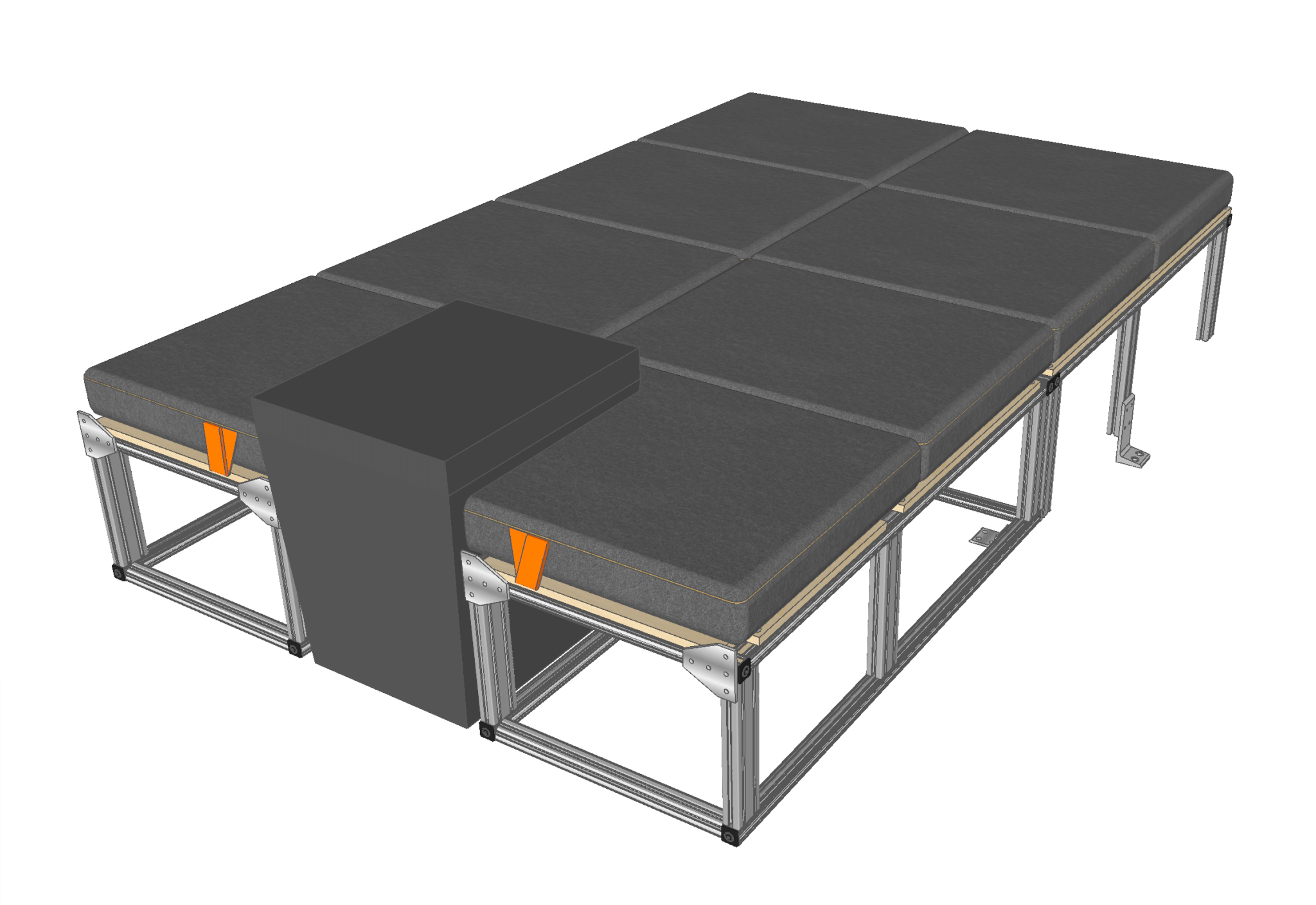

When in the sleeping configuration, we wanted enough room to sit up in bed. So this limited the height of the sleeping platform. Our Yeti Roadie 24 cooler wouldn’t fit under any reasonable sleeping platform, so we made a cutout for the cooler. The cooler can slide out through the back door of the van, and can be accessed when in sleeping mode (and acts as a small table).

Construction

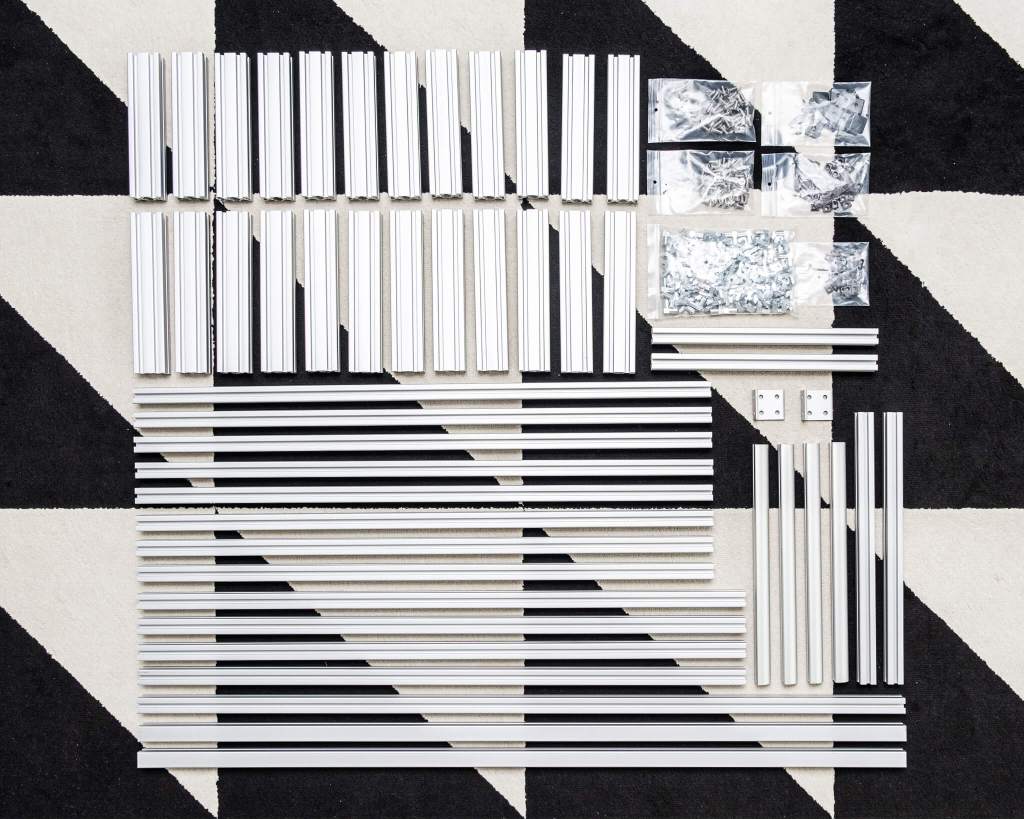

With final plans, we picked up a sheet of 12mm baltic birch plywood from my favourite lumber yard, Peacock Lumber, and ordered the t-slot extrusions and connectors online from Faztek, a Canadian supplier of t-slot aluminum.

The best part of working with t-slot aluminum is the ability to order the specific lengths you require at no extra cost. This saves a lot of work compares to cutting the aluminum extrusions yourself. Extrusions are cut with exacting precision and our Faztek order was shipped within 24 hours.

The majority of the construction work involved the plywood sleeping platform. I had the lumber yard make a raw cut through the sheet of plywood to help transport it home, but then I needed to cut it down to the precise size for the sleeping platform. A table saw would have been perfect for this, but since I only have a jig saw, I used a Bora saw guide to get a straight cut.

Then, to minimize condensation between the mattress and sleeping platform, I drilled 150 one-inch holes into the plywood. To make clean cuts, I used a Forstner bit and drilled from both sides.

I also drilled holes that would be used to bolt the plywood platform to the aluminum structure. I used a hand countersink tool and flathead bolts to make a perfectly flat sleeping platform.

After all this, I meticulously hand-sanded all the edges (rather tedious due to the 150 holes). I finished the plywood using Osmo Polyx-Oil (matte finish).

Assembly

With our finished plywood platform, dozens of aluminum extrusions and hundreds of connector pieces, it was time to start assembly.

Assembling the aluminum structure was like making an adult Meccano set.

We used standard 1-inch square extrusions (10 series), designed for lighter-duty applications. We uses a few 1×2-inch extrusions for legs to add extra stability.

For connections, there are several connector pieces to choose from. Some connectors require machining the aluminum extrusions, while others simply screw into the slots. Connectors requiring machining are typically more robust, but we opted for simplicity with simple inside hidden corner connectors. Except that our design required over 100 of them.

One thing to keep in mind with the t-slot system is the concept of a captive slot. Some components need to be slotted in from the end. You need to make sure you slot these in in the correct order, and before capping off the end. Luckily, other components can be dropped into the slot.

A few 5-hole tee joining plates are used to connect the two layers when in shelf configuration, and are re-used to secure them side-by-side when in sleeping configuration.

Final product

With everything assembled, we brought the structure into the van and secured it to the van’s tie-down points.

All was left was to give our new camper van conversion a test run at our favourite local campground.

Let us know what you think of our t-slot aluminum camper van conversion in the comments below!

Leave a comment